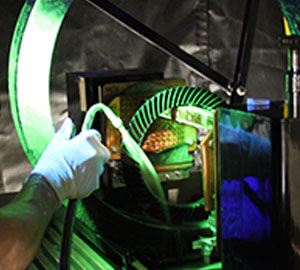

The principle of liquid penetrant testing is that the liquid penetrant is drawn into the surface-breaking crack by capillary action and excess surface penetrant is then removed; a developer (typically a dry powder) is then applied to the surface, to draw out the penetrant in the crack and produce a surface indication.

The principle of the method is that the specimen is magnetised to produce magnetic lines of force, or flux, in the material. If these lines of force meet a discontinuity, such as a crack, secondary magnetic poles are created at the faces of the crack.

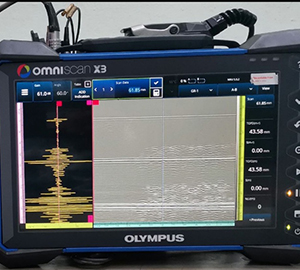

Ultrasonic testing is a versatile NDT method. Many techniques have been developed to allow full volumetric inspection of a large range of components made from a wide variety of materials. It is probably the most important method used in industries.

Radiography uses X-rays or gamma rays to produce an image of an object on film. X-rays and gamma-rays are very short wavelength electromagnetic radiation which can pass through solid material, being partly absorbed during transmission. Thus, an image is obtained on the film.

Visual inspection, with or without optical aids, many defects are surface-breaking and can be detected by careful direct visual inspection. Optical aids include low power magnifiers, microscopes, telescopes and also specialised devices such as boroscopes, endoscopes and other fibreoptic devices for the inspection of restricted access areas.

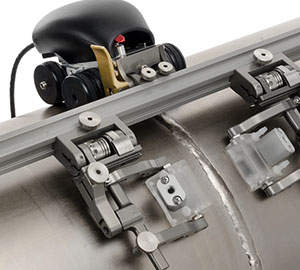

Phased Array is an ultrasonic testing technique that uses specialized multi element “array” transducers and pulses those elements separately in a patterned sequence called “phasing”. This phasing sequence allows wave steering, focusing, and scanning. This is all performed electronically.

In a TOFD system, a pair of ultrasonic probes sits on opposite sides of a weld. One of the probes, the transmitter, emits an ultrasonic pulse that is picked up by the probe on the other side, the receiver. When a crack is present, there is a diffraction of the ultrasonic wave from the tip(s) of the crack.

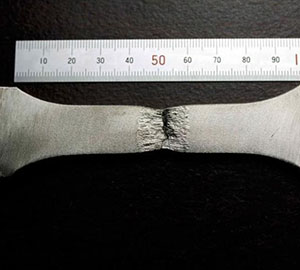

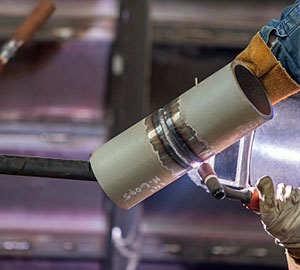

A Welding Procedure Specification or WPS, is a document that serves as a guide for the effective creation of a weld that meets all applicable code requirements and production standards.

We have been familiar in preparing WPS as per ASME sec 9, AWS D1.1, ISO 15614, ASME b31.3, AS/NZS 1554.1 & Aws D17.1 for all grade materials we have well exposure in preparing muliti process WPS and its PQR.

We have qualified welders and welding operators as per the client requirements across various standards such as ASME sec 9, AWS d1.1, ISO 9606 in wide range of materials

Our welding specialists provide third party witnessing of weld specification, procedure qualification and welder qualifications when you need independent verification.

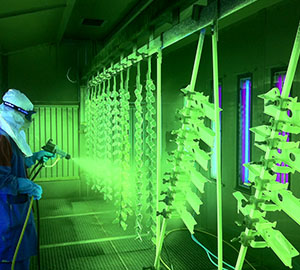

Coating inspector checks industrial equipment to ensure protective coatings were correctly applied and minimize corrosion risk. Manufacturing plants, roadway projects such as bridges, and other major industries that utilize paint need coating inspectors for quality assurance. Performs qualifications of coating processes. Checks surface preparation. Checks and records atmospheric conditions prior to starting of painting operations. Carries out wet and dry film thickness checks.

A procedure can be approved for use after a review and acceptance by a certified NDT level 3. The review process outlines all requirements from codes, specifications and/or standards and ensures that all inspection requirements are met using the procedure.

Our NDT specialists are backed up by years of experience from highly qualified personnel. These specialist techniques can assist you in meeting the inspection challenges that arise with complex components or structures and increase the detection of defects.